Efficient design of embedded systems and IPC component heat sinks

EKL heat sinks for embedded systems

Challenges and solutions for embedded PC cooling

An embedded system is usually compact, energy-efficient and designed for reliability in real-time operation. However, the compact design also results in components with high heat generation in a small space, with little room for cooling solutions. The constantly increasing computing capacities of embedded computers and the ongoing development in the field of embedded hardware place high demands on cooling technologies. Especially in the areas of POS hardware and HMI hardware, where embedded computing plays a central role, it is crucial to implement efficient cooling systems. They ensure the ideal operating temperature and minimise power loss.

Efficient heat dissipation: passive and active EKL cooling solutions for embedded systems

Choosing the right cooling solution for embedded hardware depends on various factors, such as the power dissipation of the system, the available installation space and the specific environmental conditions.

Passive cooling, using a heatpipe heatsink on a heatspreader or copper inlay, is often the preferred solution as these heatsinks have no moving parts and are largely maintenance-free and very durable.

In embedded system applications that require active cooling, fans or liquid cooling systems can be used to ensure efficient heat dissipation. Fans transport warm air out of the housing. This effectively supports the heat sink in maintaining an ideal operating temperature.

EKL offers an extensive range of fans from leading manufacturers for various requirements, including ebm papst, Adda, Everflow, STK and Sanyo Denki.

Passive cooling, using a heatpipe heatsink on a heatspreader or copper inlay, is often the preferred solution as these heatsinks have no moving parts and are largely maintenance-free and very durable.

In embedded system applications that require active cooling, fans or liquid cooling systems can be used to ensure efficient heat dissipation. Fans transport warm air out of the housing. This effectively supports the heat sink in maintaining an ideal operating temperature.

EKL offers an extensive range of fans from leading manufacturers for various requirements, including ebm papst, Adda, Everflow, STK and Sanyo Denki.

Your heat sink manufacturer for embedded hardware

EKL has been the experienced specialist at your side in embedded system design for 30 years. We will find a customised and cost-optimised cooling solution for you to ensure the performance and reliability of your embedded systems in a wide range of applications.

Let's talk about your cooling task!

Thomas Würzer

Sales Department

+49 (0)7561 9837-44

t.wuerzer@ekl-ag.de

Make an appointment Enquiries by e-mail

Thomas Würzer

Sales Department

+49 (0)7561 9837-44

t.wuerzer@ekl-ag.de

Make an appointment Enquiries by e-mail

Typical applications for EKL heat sinks in embedded hardware

In electronics, the heat generated by current-carrying components is an unavoidable and usually annoying side effect. As a product manager and development engineer of electronic systems, free yourself from the risk of overheating and expensive development loops by placing the thermal management of your device in the hands of EKL! We see ourselves as a partner in your development, pursuing the same goals as you: to manufacture a reliable, high-quality and durable product at competitive prices.

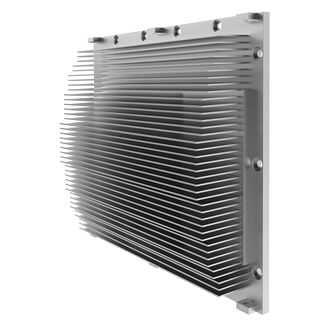

POS display heat sinks

For the integration of POS displays and POS hardware in systems with limited space, standard heat sinks are often not compatible or powerful enough to effectively cool the heat loss of the components. EKL develops specialised POS display cooling systems for you that are both space-saving and powerful. We specialise in economical cooling solutions that guarantee the ideal operating temperature and functionality of your POS displays.

HMI display heat sinks

Compact and powerful HMI systems are the centrepiece of modern embedded systems. They combine HMI computers, HMI hardware and HMI touch displays in one device to ensure maximum mobility and user-friendliness. The HMI panel PCs are designed to offer high processing power despite their small size. With the efficient heat sink solutions from EKL, the heat loss is dissipated quickly and reliably. In this way, the electronic components maintain a constant and reliable performance, which is essential for the demanding tasks of embedded hardware.

Embedded PC hardware

In the world of embedded PCs, heat dissipation is a critical issue. Hardware used in embedded computers often has to operate in compact enclosures where passive cooling systems cannot provide sufficient cooling capacity. To bring your embedded system testing to a successful conclusion, your device must not overheat even under load and adverse conditions. With EKL at your side as your development partner, you can get your product ready for series production faster thanks to efficient cooling and keep development costs and product costs under control.

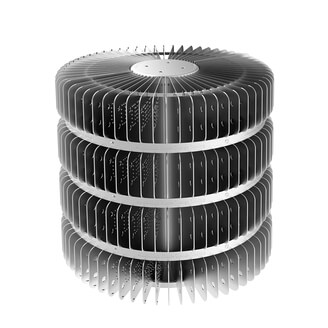

High-performance heat sinks for embedded systems

EKL - Everything from a single source

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

Personal point of contact

From the initial project phase to the delivery of your customised cooling technology, you will always have a personal point of contact at EKL We are always available to provide you with competent and responsive support.

Full service from the idea to logistics

Concentrate your core competence on product development. We offer all project services relating to cooling - from the initial consultation, idea development and thermal simulation, prototype construction and optimisation, through to punctual delivery and reliable logistics and warehousing.

Variety of manufacturing technologies

We are one of the heat sink manufacturers with the widest range of manufacturing technologies. This enables us to offer a service portfolio that is designed for the development and production of your truly best cooling solution - at an excellent price-performance ratio.

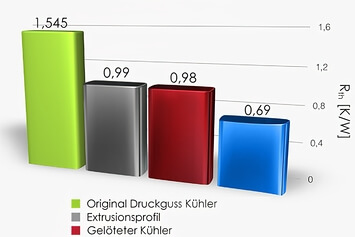

Performance optimisation + cost optimisation

EKL actively supports you in reducing your manufacturing costs without compromising quality or performance. Product cost reduction is an important aspect that we achieve for you through efficient design, careful material selection and reliable manufacturing partners.

Pre-assembled assemblies + packaging

We actively assist your production staff by supplying pre-assembled assemblies. This not only reduces your labour costs per device, but also guarantees the highest quality. Your sensitive heat sinks or assemblies are protected for transport using customised packaging.

Warehouse and logistics in Germany

With over 1100 pallet spaces, we offer tailor-made logistics solutions and minimise your storage costs through stockpiling and consignment stock, just-in-time deliveries, coordinated delivery schedules and flexible shipping options for individual requirements.

The EKL project stages for your cooling solutionChoose your point of entry!

Our offer is as flexible as your needs. Are you still early in the development phase and want an idea generator for the best cooling solution? Do you have a ready-made device that gets too hot? Or are you simply looking for an alternative or additional supplier for a heat sink already used in series production? In EKL you will always find a flexible, agile and responsible partner for the cooling of your electronic components and complete systems, whatever the project phase. We look forward to your enquiry!

Counselling

Concept

Concept

In personal contact and open dialogue with you, our engineers create the creative space and framework to design the best cooling solution for your requirements from the wealth of options available.

Development

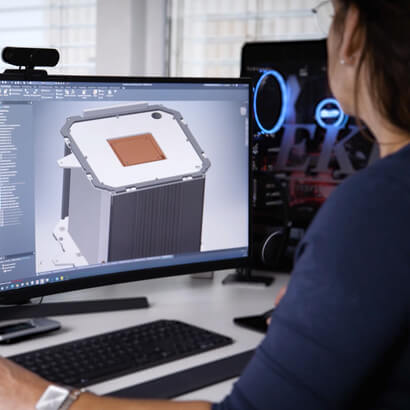

Feasibility / simulation

Feasibility / simulation

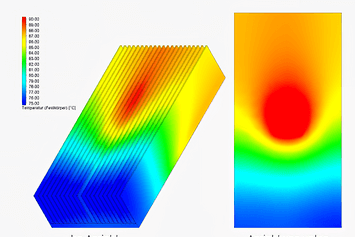

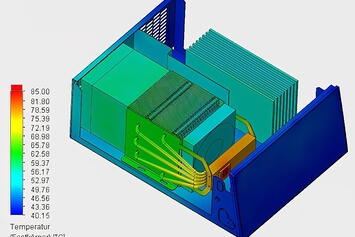

We test the idea for your heat sink virtually in the thermal simulation. Realistic computer simulations allow variations in manufacturing processes, system structures and other parameters.

Performance optimisation

Even a well-functioning heat sink can still be optimised. We determine the "how" and "how much" by simulating different materials or cooling technologies, for example, as well as simulating various environmental parameters.

Cost optimisation

An expensive heat sink can often be made significantly cheaper by using an alternative manufacturing process. Whether with the same or application-specific performance: we support your product development in reducing costs.

Production drawing

Prototype construction

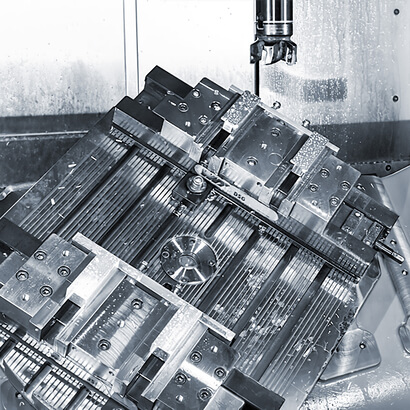

Prototype construction

Prototypes from our design department enable early testing and targeted solutions to problems in your device. We create your functional and design prototypes with our in-house CNC production.

Series production

small to large

small to large

By manufacturing in-house and in Asia, we can offer all types of heat sinks from small to large series at competitive unit prices. We impress our long-standing customers with our consistently high quality.

Sampling

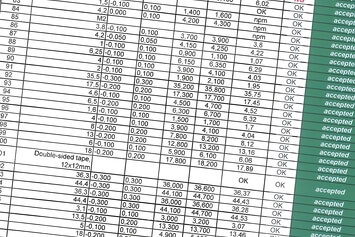

Incoming goods inspection

Incoming goods inspection

We make no compromises when it comes to quality: Development takes place in Germany and all series products are analysed by our German test laboratory according to test plans using state-of-the-art methods.

Surface finishing

Anodising, powder coating, painting etc. protect your heat sinks from corrosion and environmental influences. But colour is not just chic, because dark-coloured heat sinks also emit more radiant heat.

Assemblies

Pre-assembly

Pre-assembly

We actively relieve your production with pre-assembled assemblies. This reduces your workload per device and guarantees the highest quality, because as cooling professionals we ensure that the heat sink is optimally attached.

Quality assurance

Test plans

Test plans

We test according to our own and customer-specific test plans using the latest rapid thermal measuring equipment, 3D measuring machines, assembly tests and testing of various application scenarios.

Packaging design

Packaging production

Packaging production

EKL develops and produces customised packaging to optimally protect your sensitive heat sinks or assemblies in the sometimes harsh transport and storage environments.

Warehouse

& Logistics

& Logistics

With large storage capacities, we offer production-related stocking and consignment warehouses, just-in-time deliveries, customised delivery schedules and flexible shipping options for your individual requirements.

Let's talk about your cooling task!

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail