Thermal heat sink simulation saves time and money

How we use thermal simulation to cool your electronics in a cost-optimised way

Life as a developer in electronics would be much easier if the components used simply fulfilled their function without becoming warm or even hot. This is why the cooling solution is often seen as a "chore" and placed at the end of the concept and development work.

Preventing performance losses and heat death

This can quickly become very expensive if prototypes or even series devices become too hot during operation and time-consuming development steps have to be repeated.

With thermal simulation in virtual environments, EKL offers you a realistic method to run through a variety of best-case and worst-case scenarios in the shortest possible time - and without using any materials. Our specialisation in electronic heat sinks and 30 years of experience in their development and production helps us to approach the selection of alternative coolers for the simulation in a targeted and results-oriented manner.

Preventing performance losses and heat death

This can quickly become very expensive if prototypes or even series devices become too hot during operation and time-consuming development steps have to be repeated.

With thermal simulation in virtual environments, EKL offers you a realistic method to run through a variety of best-case and worst-case scenarios in the shortest possible time - and without using any materials. Our specialisation in electronic heat sinks and 30 years of experience in their development and production helps us to approach the selection of alternative coolers for the simulation in a targeted and results-oriented manner.

Let's talk about your cooling task!

Dr Andreas Engelhardt

Head of Development and Design

a.engelhardt@ekl-ag.de

Make an appointment Enquiries by e-mail

Dr Andreas Engelhardt

Head of Development and Design

a.engelhardt@ekl-ag.de

Make an appointment Enquiries by e-mail

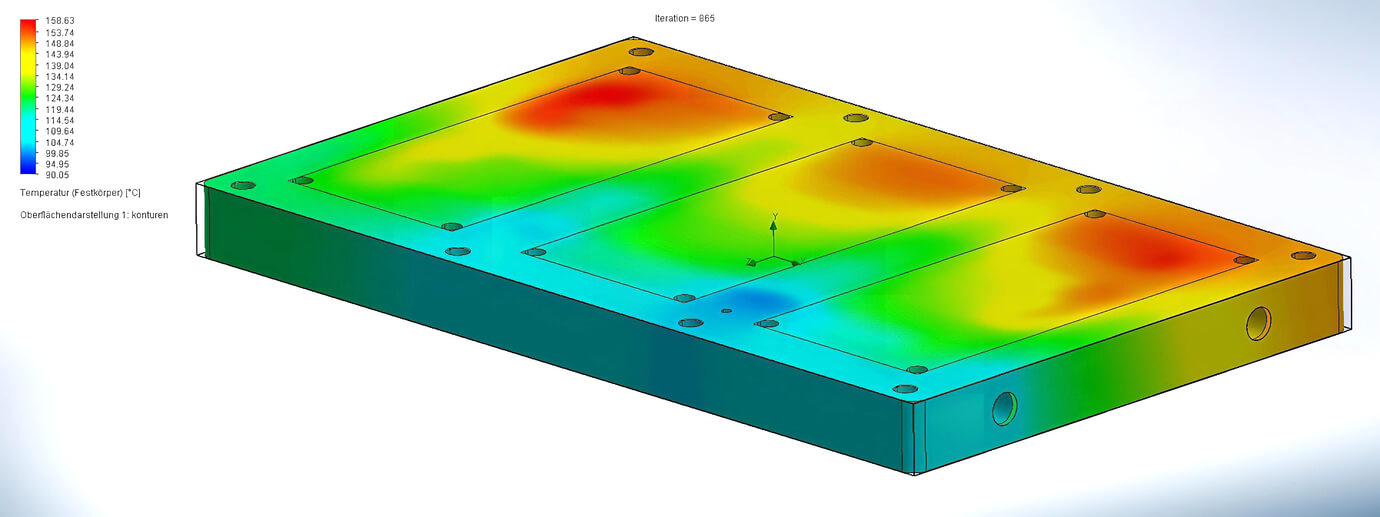

State-of-the-art simulation software based on CFD methods

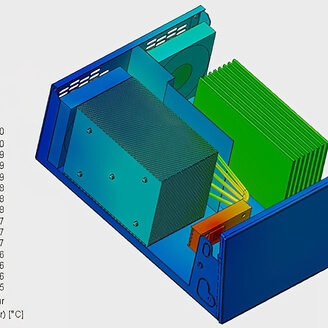

We work with the simulation software FloEFD™ from Siemens, which is based on CFD (Computational Fluid Dynamics) methods. In combination with the latest hardware, we have high computer performance to keep simulation times short. Variable temperature developments and flow conditions can be visualised very realistically and reliably.

As a result, you receive a selection of cooling solutions that provides you with a valid basis for decision-making based on parameters such as

As a result, you receive a selection of cooling solutions that provides you with a valid basis for decision-making based on parameters such as

- Size

- Production technology

- design

Simulation of heat sink alternatives in the system design

The earlier you incorporate the EKL simulation process into your development, the more optimisation potential there can be for your device, e.g:

- Size reduction with the same performance

- Changed arrangement of components on the circuit board / in the device

- Size and number of ventilation slots in the housing

- Optimisation of air intake and air removal

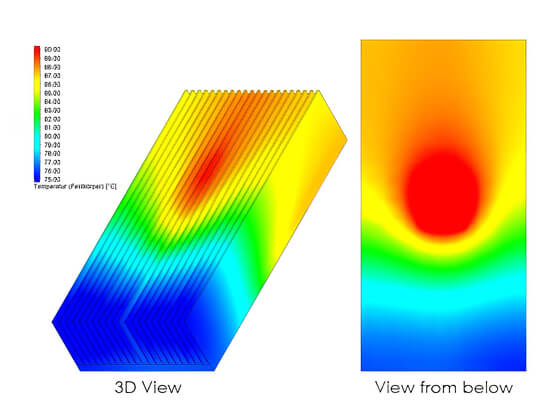

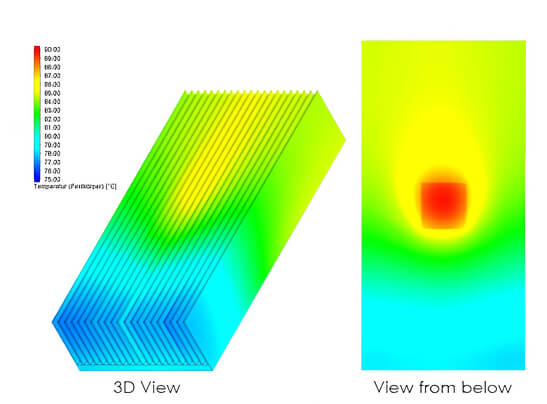

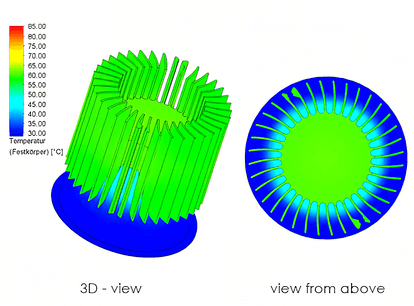

Example simulation: Material comparison of a forced-cooled finned heat sink

In the following heat sink, a fan ensures forced ventilation (the fan is not shown in the simulation):

Thermal simulation aluminium heat sink

Thermal simulation copper heat sink

Evaluation and basis for decision-making

The evaluation clearly shows the influence of the material on the cooling performance compared to the weight. The better thermal conductivity of copper distributes the waste heat more quickly to all the cooling fins. More surface area is utilised for heat radiation. Taking into account the significantly higher material price of copper, you as a customer can now make the best decision for you. Or assign EKL to simulate alternative manufacturing processes in order to find the most efficient and cost-effective solution for your device.

Your advantages of simulating heat dissipation processes:

- Early detection and elimination of thermal problems

- Varying the materials and fans

- Determination of a cost-optimised cooling solution

- No material and prototype costs

- No unnecessary development loops and additional labour costs

- No unnecessary loss of time in the time-to-market

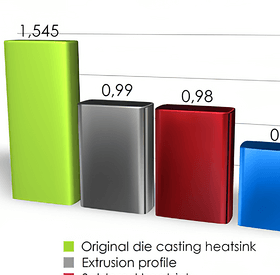

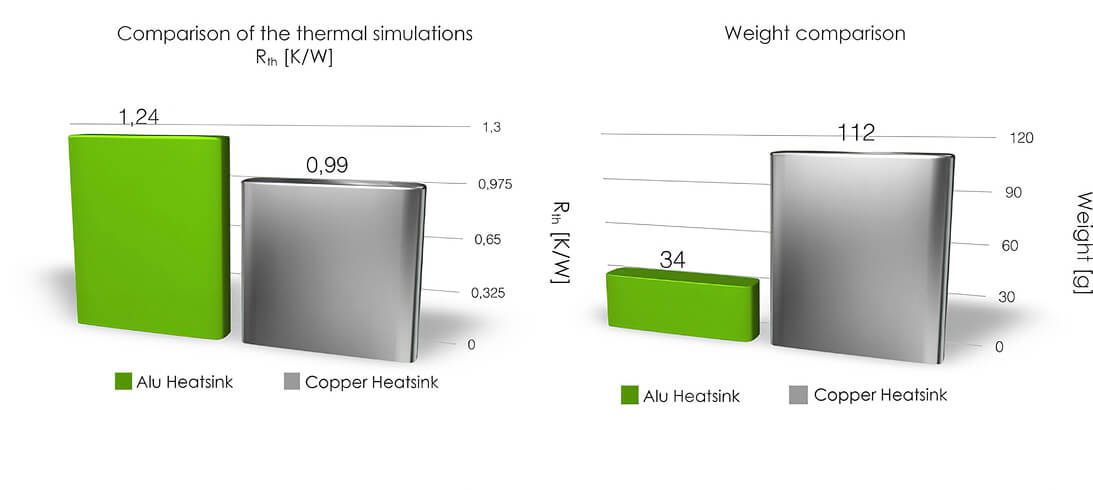

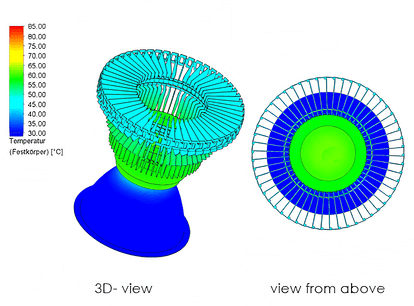

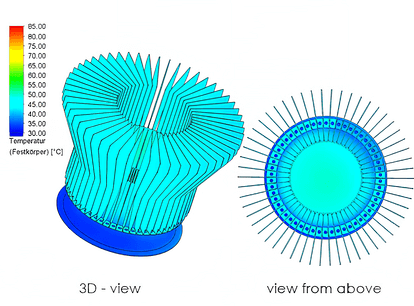

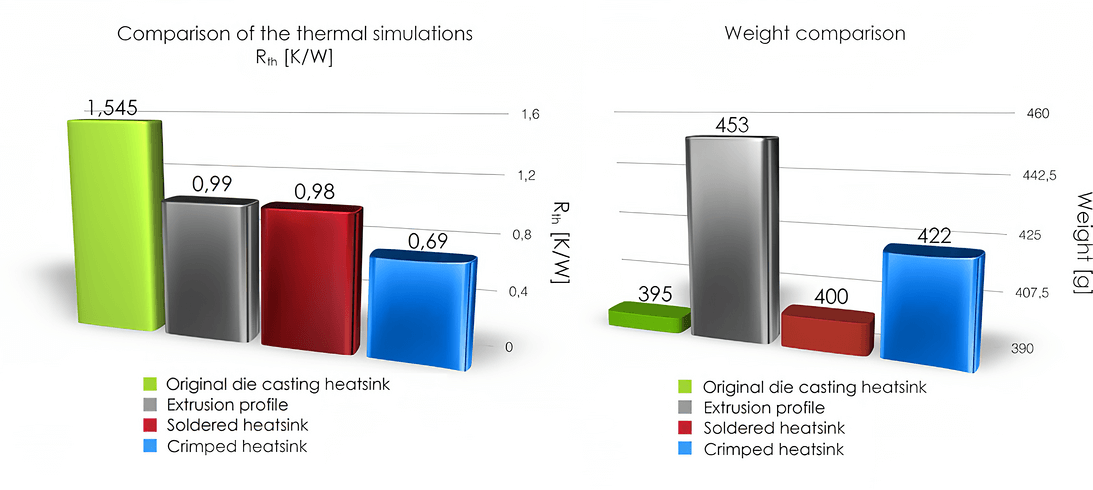

Example simulation: Increasing cooling capacity by comparing alternative manufacturing processes

A customer was previously using die-cast heat sinks and was looking for an alternative heat sink with a higher cooling capacity. However, the new heat sink should not be significantly heavier.

Thermal simulation of the die-cast heat sink used

Thermal simulation with an extruded heat sink

Thermal simulation with a soldered heat sink

Thermal simulation with a crimped heat sink

Evaluation and basis for decision-making

The simulation result shows that the soldered heat sink offers significantly better heat dissipation at a similarly low weight (as the previous die-cast aluminium heat sink).

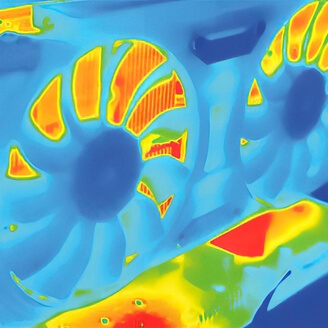

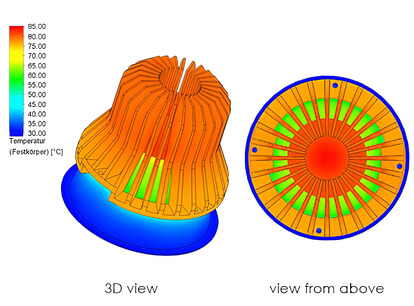

Example simulation: New product development with early inclusion of the cooling solution

Are you still in the early development phase of your device and don't want any surprises later on due to heat development? Then EKL, as your development partner, can provide you with reliable cost and performance values for your cooling solution with the help of thermal simulation.

Especially if you want to offer a device in different performance classes. Low power generally generates less power loss that needs to be cooled. This allows you to install a less expensive cooling solution, which is reflected in a more favourable product costing.

If the performance of the device increases, the cooling capacity and cost increase should remain in balance. Your electronic product should not only function reliably, but also remain competitively priced.

Especially if you want to offer a device in different performance classes. Low power generally generates less power loss that needs to be cooled. This allows you to install a less expensive cooling solution, which is reflected in a more favourable product costing.

If the performance of the device increases, the cooling capacity and cost increase should remain in balance. Your electronic product should not only function reliably, but also remain competitively priced.

Variation of component design and cooling solutions

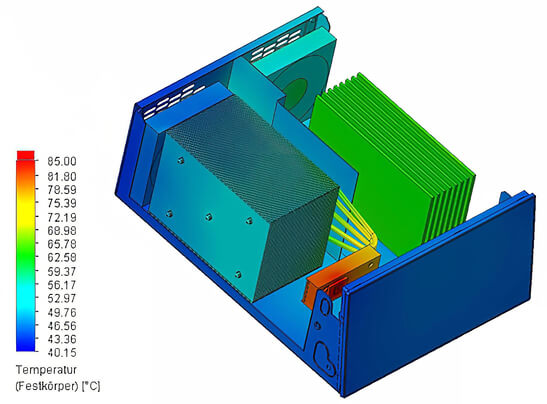

In the following scenario, the customer had not yet planned a cooling solution for his application. Our EKL development staff were able to design several simulation models based on the requirements:

Simulation model 1:

Large heat sink with long fins

One fan on the heat sink

An additional fan on the housing

5 x Ø6 mm heatpipes

(long heatpipes = power loss)

Large heat sink with long fins

One fan on the heat sink

An additional fan on the housing

5 x Ø6 mm heatpipes

(long heatpipes = power loss)

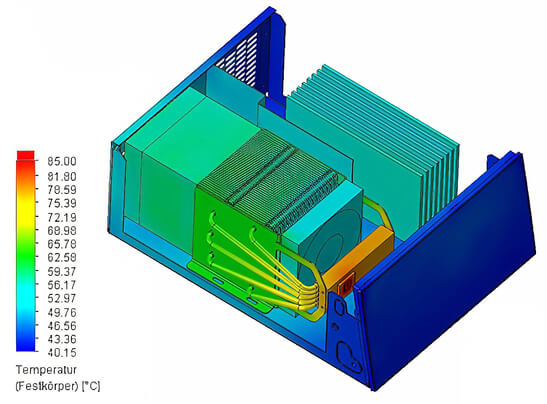

Simulation model 2:

Shorter heat sink = less pressure loss

The additional fan has now been mounted on the heat sink

5 x Ø6 mm heatpipes

(shorter heatpipes = less power loss)

Shorter heat sink = less pressure loss

The additional fan has now been mounted on the heat sink

5 x Ø6 mm heatpipes

(shorter heatpipes = less power loss)

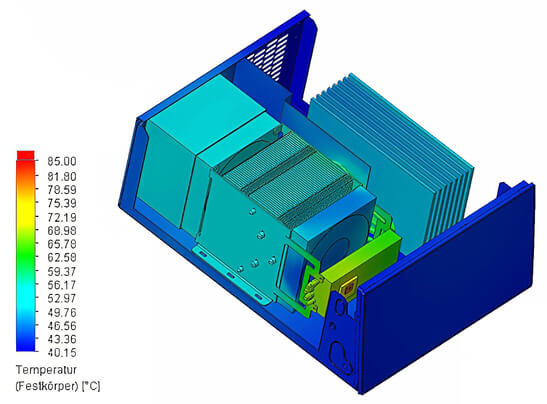

Simulation model 3:

Shorter heat sink (less pressure loss)

The additional fan has now been mounted on the heat sink

2 x Ø6 mm heatpipes

3 x Ø8 mm heatpipes

Shorter heat sink (less pressure loss)

The additional fan has now been mounted on the heat sink

2 x Ø6 mm heatpipes

3 x Ø8 mm heatpipes

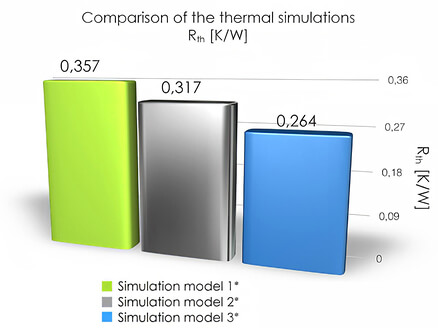

Evaluation and basis for decision-making

Simulation model 3 shows a 35 % higher cooling capacity than simulation model 1.

Your advantages of simulation in heat sink calculation

- Avoidance of thermal problems in advance

- Massive time savings during development

- Avoidance of unnecessary development loops with prototype and labour costs

- Predictable development costs

- Shorter prototype phase

- Performance and cost-optimised cooling solution

- Early detection of hot spots

- Ideas and advice regarding optimisation potential in the entire system design

Get to know more EKL expertise

EKL - Everything from a single source

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

The temperature of electronic components must remain within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL provides you with expert support in solving these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management technologies.

EKL is therefore your perfect solution partner for cost-optimised temperature regulation of all components in your electronic device. We are at your side in every project phase, from the initial idea, design and prototype construction through to series production - and beyond!

Personal point of contact

From the initial project phase to the delivery of your customised cooling technology, you will always have a personal point of contact at EKL We are always available to provide you with competent and responsive support.

Full service from the idea to logistics

Concentrate your core competence on product development. We offer all project services relating to cooling - from the initial consultation, idea development and thermal simulation, prototype construction and optimisation, through to punctual delivery and reliable logistics and warehousing.

Variety of manufacturing technologies

We are one of the heat sink manufacturers with the widest range of manufacturing technologies. This enables us to offer a service portfolio that is designed for the development and production of your truly best cooling solution - at an excellent price-performance ratio.

Performance optimisation + cost optimisation

EKL actively supports you in reducing your manufacturing costs without compromising quality or performance. Product cost reduction is an important aspect that we achieve for you through efficient design, careful material selection and reliable manufacturing partners.

Pre-assembled assemblies + packaging

We actively assist your production staff by supplying pre-assembled assemblies. This not only reduces your labour costs per device, but also guarantees the highest quality. Your sensitive heat sinks or assemblies are protected for transport using customised packaging.

Warehouse and logistics in Germany

With over 1100 pallet spaces, we offer tailor-made logistics solutions and minimise your storage costs through stockpiling and consignment stock, just-in-time deliveries, coordinated delivery schedules and flexible shipping options for individual requirements.

Let's talk about your cooling task!

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail