Which material for which heat sink?Choosing the right heat sink material

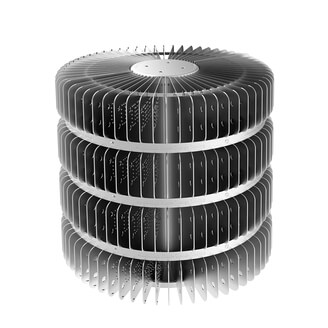

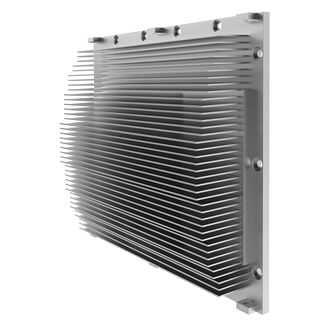

Aluminium heat sink

Aluminium has established itself as the preferred material for heat sinks, although it is a much weaker heat conductor than copper. Nevertheless, aluminium heat sinks impress with their excellent heat transfer, light weight and reasonable material price. Aluminium heat sinks are usually used in the form of continuous cast or die-cast alloys. Pure aluminium is also used for aluminium heat sinks using cold forging and skived-fin processes, especially for cold extruded pin-fin heat sinks.

Copper heat sink

Copper is known as an excellent heat conductor and is often used for copper heat sinks. It is primarily chosen when large amounts of heat need to be dissipated quickly and the available space is limited. However, small copper plates also act as an ideal CPU heat spreader material for CPU heat sinks in order to quickly transfer the processor heat to the aluminium heat sink mounted above it. Due to its higher price and weight, copper is more frequently used for heat sinks in small-volume components. Copper heatsinks, such as compact skived heatsinks with very thin fins, are generally used in combination with a fan. The thin heat pipes of the heatpipes are also preferably made from copper, which is easy to mould.

Magnesium die-cast heat sink

Magnesium offers an impressive combination of lightness and strength, which can make it an alternative to aluminium. It is characterised by its high load-bearing capacity and strength, although its thermal conductivity is somewhat lower than that of aluminium. Due to its crystalline structure, magnesium is comparatively brittle and can break under load at room temperature. Magnesium can be an alternative for special applications that primarily require a reduction in weight.

Stainless steel heat sink

Sheet steel is a relatively poor heat conductor. As housings, however, sheet metal can make an additional contribution to heat dissipation by utilising the large surface area as a housing cooler to radiate heat.

Silver heat sink

Although silver has excellent thermal conductivity, it disqualifies itself as a heat sink material due to its approximately 400 times higher price than aluminium.

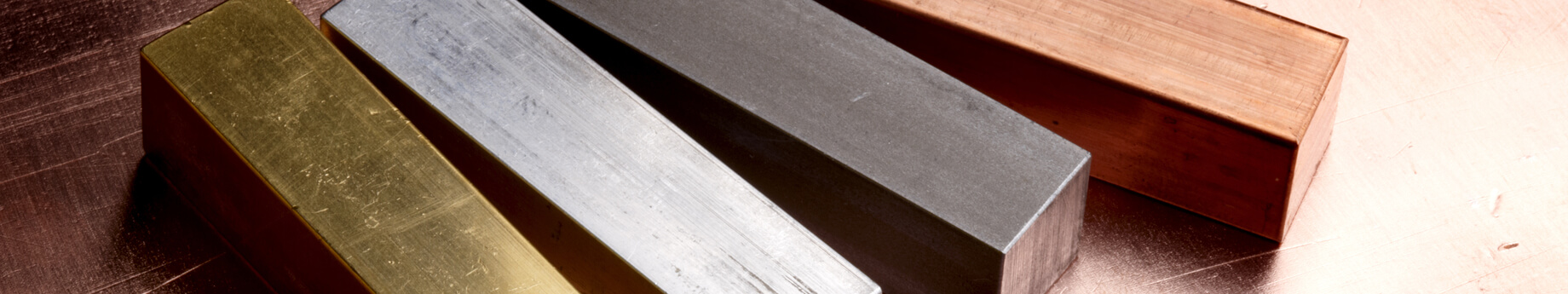

Overview of the thermal conductivity and density of different metalsHeat sink material comparison

| Material | Wärmeleitfähigkeit | Dichte |

|---|---|---|

Aluminium | 220 W/mK | 2700 kg/m³ |

Kupfer | 380 W/mK | 8933 kg/m³ |

Magnesium | 159 W/mK | 1740 kg/m³ |

Stahl | 50 W/mK | 7850 kg/m³ |

Silber | 429 W/mK | 10500 kg/ m³ |

EKL heat sink product range

Let's talk about your cooling task!

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail