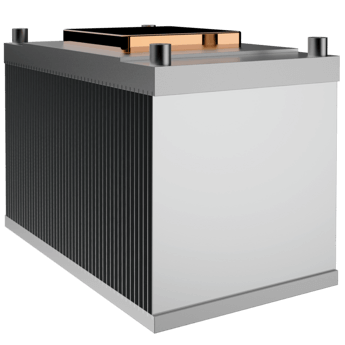

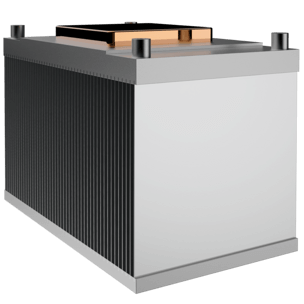

Extra high fin density with bonded cooling fins

Bonded fin heat sinks offer maximised surface area with minimal space requirements

Heat sinks with bonded fins are characterised by an increased surface area compared to profiled heat sinks. The aluminium cooling fins are usually bonded into the grooves of a copper or aluminium base plate using an epoxy resin with good thermal conductivity. Copper is an excellent heat spreader due to its high thermal conductivity.

Advantages of the bonded cooling fin process

- Possible alternative to the soldering process

- High number of cooling fins in a small space

- Aluminium or copper or a combination possible

- Improved heat dissipation and cooling capacity due to larger surface area

- High dimensional accuracy, no material distortion during production

- Small quantities feasible

- Customised design of thicknesses and geometries of the material for base plate cooling fins

- High-performance cooling in combination with a fan

- Various surface finishes possible (anodising, chromating, painting, powder coating, etc.)

High-performance heat sinks with the help of forced ventilation

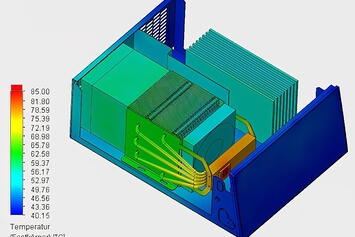

The bonded fin process allows an extremely dense arrangement of very thin cooling fins on the heat sink plate. Assembly is nevertheless quick and cost-effective. The larger surface area improves heat dissipation, as more space is available for heat transfer to the ambient air. However, if the fin density is very high, the natural air flow between the fins may no longer be sufficient. Convection is then actively supported by a fan.

Another advantage of bonded cooling fins is their flexibility in terms of design. Bonded fin heatsinks can be flexibly manufactured in different sizes and shapes to meet the specific requirements of an electronic component or system. In addition, the use of adhesives allows for even heat transfer between the fins and the base plate, resulting in efficient cooling performance.

Performance increase of bonded cooling fins through combination with various techniques

Heat sinks with bonded fins can be manufactured with very high fin density. This enables improved heat dissipation to the ambient air due to the increased surface area and therefore more efficient cooling. In combination with other cooling technologies, these bonded fin heat sinks can further increase heat dissipation. They are ideal for high-performance components that require intensive cooling.

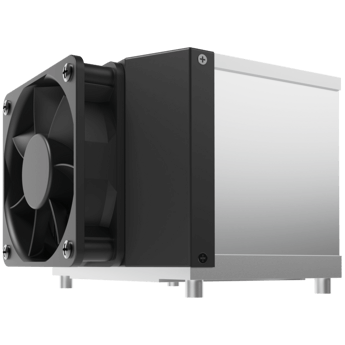

Bonded Fin heat sink+ fan

The combination of bonded fin heat sinks with forced ventilation accelerates the removal of heat and thus offers higher cooling capacities. They also work effectively in environments with little or no natural convection. The use of a fan allows increased fin density for improved heat transfer. The smaller installation space required and the smaller size compared to systems with free convection allow a more compact design. EKL offers a wide range of its own fan models as well as fans from well-known brands such as ebm-papst, SANYO DENKI, ADDA, JAMICON, STK and Everflow.

Bonded Fin heat sink+ copper insert

The faster heat spread ensures more efficient dissipation of heat from electronic components. Compared to full copper coolers, this combination enables significant weight savings. In addition, the copper insert provides a buffer for power peaks.

Bonded Fin heat sink+ heatpipes

The faster heat spreading through heat pipes distributes the heat efficiently over the bonded fins of the heat sink, which enables even heat distribution. This helps to avoid hotspots and transport the heat to more distant locations, which is particularly important in compact systems. At the same time, weight is saved without compromising cooling performance.

Bonded Fin heat sink+ vapour chamber

The functional principle of the vapour chamber accelerates the heat spread, the heat is efficiently dissipated from the source to the bonded fins. The bonded fins ensure an even distribution of heat over a large surface area and avoid hotspots. The vapour chamber is significantly lighter than a solid copper plate. In addition, the low temperature gradient prevents excessive thermal stress on the components, which increases service life and reliability.

Let's talk about your cooling task!

Lynne Albring

Sales Department

+49 (0)7561 9837-50

l.albring@ekl-ag.de

Make an appointment Enquiries by e-mail

Lynne Albring

Sales Department

+49 (0)7561 9837-50

l.albring@ekl-ag.de

Make an appointment Enquiries by e-mail

High cooling capacity for small installation space

Bonded Fin heat sinks are an excellent choice for cooling electronic components that have a high power loss and radiate a lot of heat. Bonded fin heat sinks are an ideal cooling solution for components with a high heat flow, such as those found in telecommunications and industrial electronics. They are also ideal for power electronics with high current flow, such as converters, inverters and motor controllers, which can generate considerable heat. Bonded Fin Heat Sinks are often used in power supplies, amplifiers and other electronic devices where efficient heat dissipation in a small space is critical.

Choosing the right heat sink depends on several factors, such as the thermal load of the component, the available space and the environmental conditions. Bonded Fin Heatsinks offer a customisable solution that can be tailored to specific requirements.

Choosing the right heat sink depends on several factors, such as the thermal load of the component, the available space and the environmental conditions. Bonded Fin Heatsinks offer a customisable solution that can be tailored to specific requirements.

Added value and extras

Our full service goes beyond the mere development, series production and logistics of your heat sinks. Do you need special bores or milling on your heat sinks? Do you want your heat sink to not only dissipate a lot of heat, but also look stylish? Would you like a product ready-to-plug-in with all accessories?

Welcome to EKL!

Welcome to EKL!

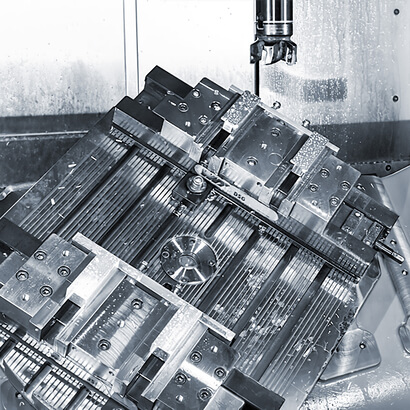

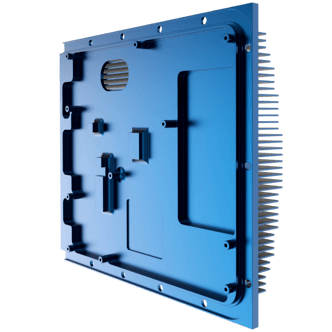

CNC machining

For prototypes, small series and customised reworking of heat sinks, we have modern 3- and 5-axis CNC milling machinesat our company headquarters. Complex machined and high-precision radiators are our speciality. Working areas of the machines:

Hermle C 400 (5-axis) 850 x 700 x 500 mm | Mikron VCE1000pro (3-axis) 1000 x 560 x 600 mm | Kondia B1050 (3-axis): 1000 x 500 x 600 mm

Hermle C 400 (5-axis) 850 x 700 x 500 mm | Mikron VCE1000pro (3-axis) 1000 x 560 x 600 mm | Kondia B1050 (3-axis): 1000 x 500 x 600 mm

Surface finishing

Our range includes various surface finishes to create a durable, corrosion-resistant surface. Nickel plating increases wear resistance and lustre. Chromating and passivation, especially with Surtec 650, provide additional protection against corrosion. Powder coating is another option for a robust and durable coloured surface. Painting and cathodic dip coating round off our wide range of surface colours and textures.

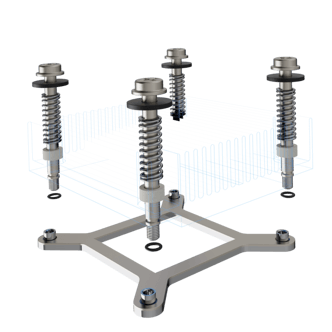

Attachments & accessories

Depending on the application, screws, springs or push pins ensure the secure and stable attachment of the heat sinks. Backplates provide additional stability and improved heat dissipation. Heat-conducting pastes and pads are naturally part of our range to enable optimum heat transfer between the heat sink and the heat source.

Secure packaging for transport

With a focus on perfect protection during transport, we develop packaging that not only fits perfectly but is also robust. Another important aspect of the range is the use of recyclable materials that contribute to sustainability and environmental friendliness.

Heat sink with bonded fins in typical application areas

Heatsinks with bonded fins are popular in many applications. The closely spaced cooling fins increase the surface area of the heat sink, which improves heat transfer to the environment. They thus keep the operating temperature of electronic components and systems within safe limits.

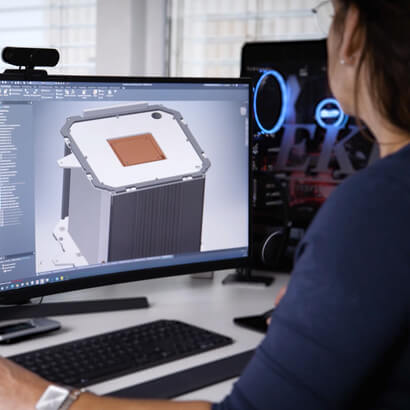

The EKL project stages for your cooling solutionChoose your point of entry!

Our offer is as flexible as your needs. Are you still early in the development phase and want an idea generator for the best cooling solution? Do you have a ready-made device that gets too hot? Or are you simply looking for an alternative or additional supplier for a heat sink already used in series production? In EKL you will always find a flexible, agile and responsible partner for the cooling of your electronic components and complete systems, whatever the project phase. We look forward to your enquiry!

Counselling

Concept

Concept

In personal contact and open dialogue with you, our engineers create the creative space and framework to design the best cooling solution for your requirements from the wealth of options available.

Development

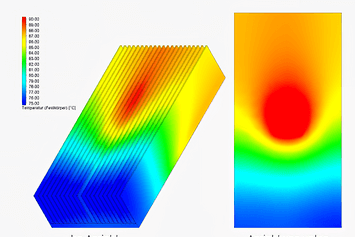

Feasibility / simulation

Feasibility / simulation

We test the idea for your heat sink virtually in the thermal simulation. Realistic computer simulations allow variations in manufacturing processes, system structures and other parameters.

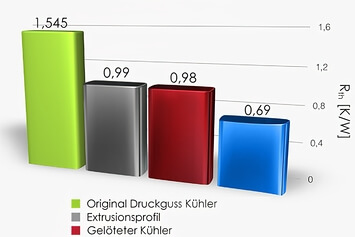

Performance optimisation

Even a well-functioning heat sink can still be optimised. We determine the "how" and "how much" by simulating different materials or cooling technologies, for example, as well as simulating various environmental parameters.

Cost optimisation

An expensive heat sink can often be made significantly cheaper by using an alternative manufacturing process. Whether with the same or application-specific performance: we support your product development in reducing costs.

Production drawing

Prototype construction

Prototype construction

Prototypes from our design department enable early testing and targeted solutions to problems in your device. We create your functional and design prototypes with our in-house CNC production.

Series production

small to large

small to large

By manufacturing in-house and in Asia, we can offer all types of heat sinks from small to large series at competitive unit prices. We impress our long-standing customers with our consistently high quality.

Sampling

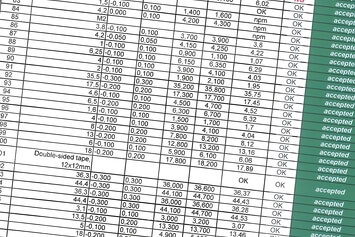

Incoming goods inspection

Incoming goods inspection

We make no compromises when it comes to quality: Development takes place in Germany and all series products are analysed by our German test laboratory according to test plans using state-of-the-art methods.

Surface finishing

Anodising, powder coating, painting etc. protect your heat sinks from corrosion and environmental influences. But colour is not just chic, because dark-coloured heat sinks also emit more radiant heat.

Assemblies

Pre-assembly

Pre-assembly

We actively relieve your production with pre-assembled assemblies. This reduces your workload per device and guarantees the highest quality, because as cooling professionals we ensure that the heat sink is optimally attached.

Quality assurance

Test plans

Test plans

We test according to our own and customer-specific test plans using the latest rapid thermal measuring equipment, 3D measuring machines, assembly tests and testing of various application scenarios.

Packaging design

Packaging production

Packaging production

EKL develops and produces customised packaging to optimally protect your sensitive heat sinks or assemblies in the sometimes harsh transport and storage environments.

Warehouse

& Logistics

& Logistics

With large storage capacities, we offer production-related stocking and consignment warehouses, just-in-time deliveries, customised delivery schedules and flexible shipping options for your individual requirements.

Bonded Cooling Fin manufacturing process in direct comparison

A filter is active, some data is hidden

• less suitable | ••••• excellently suited | n.a.: not applicable

Let's talk about your cooling task!

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail